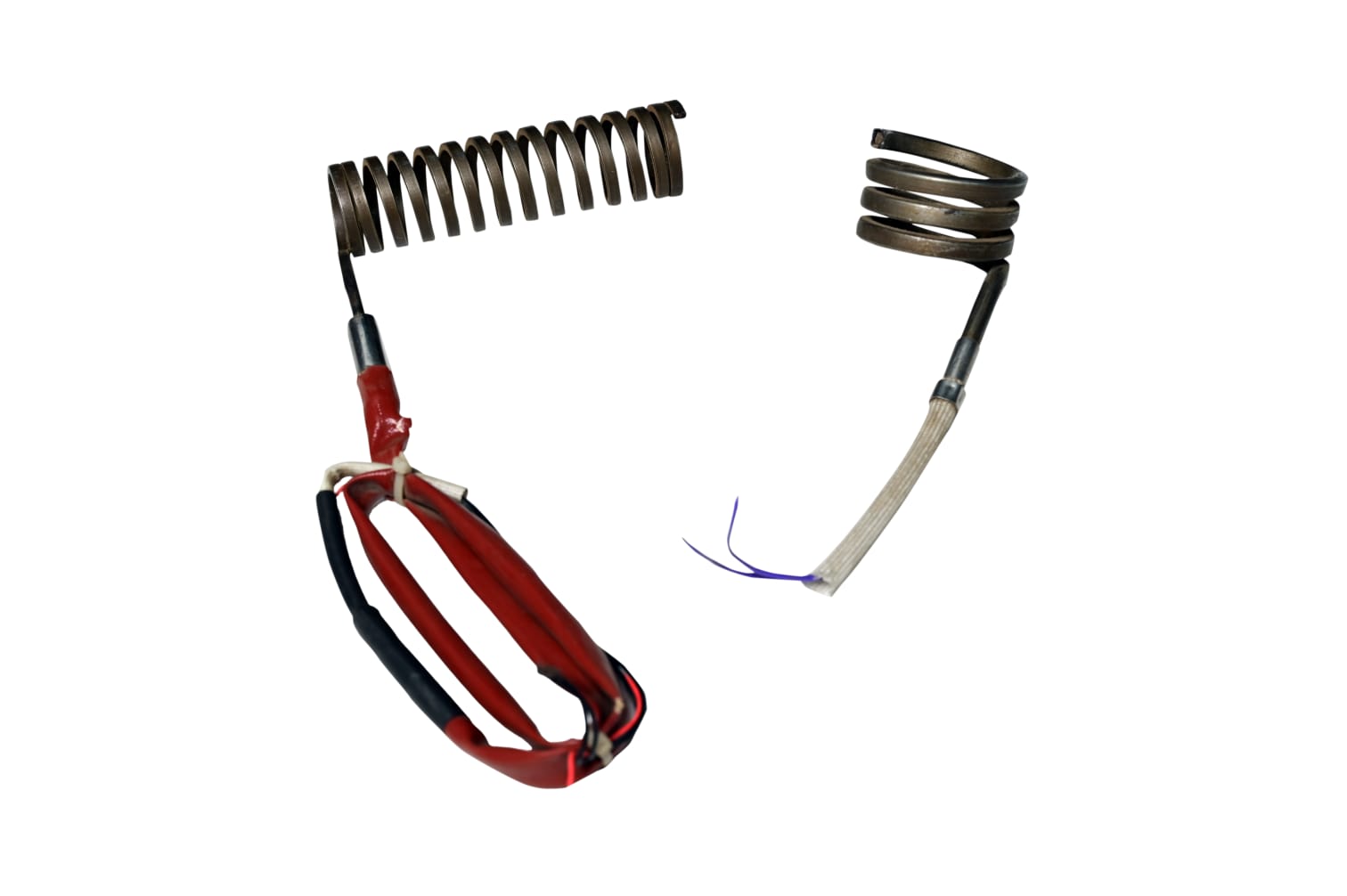

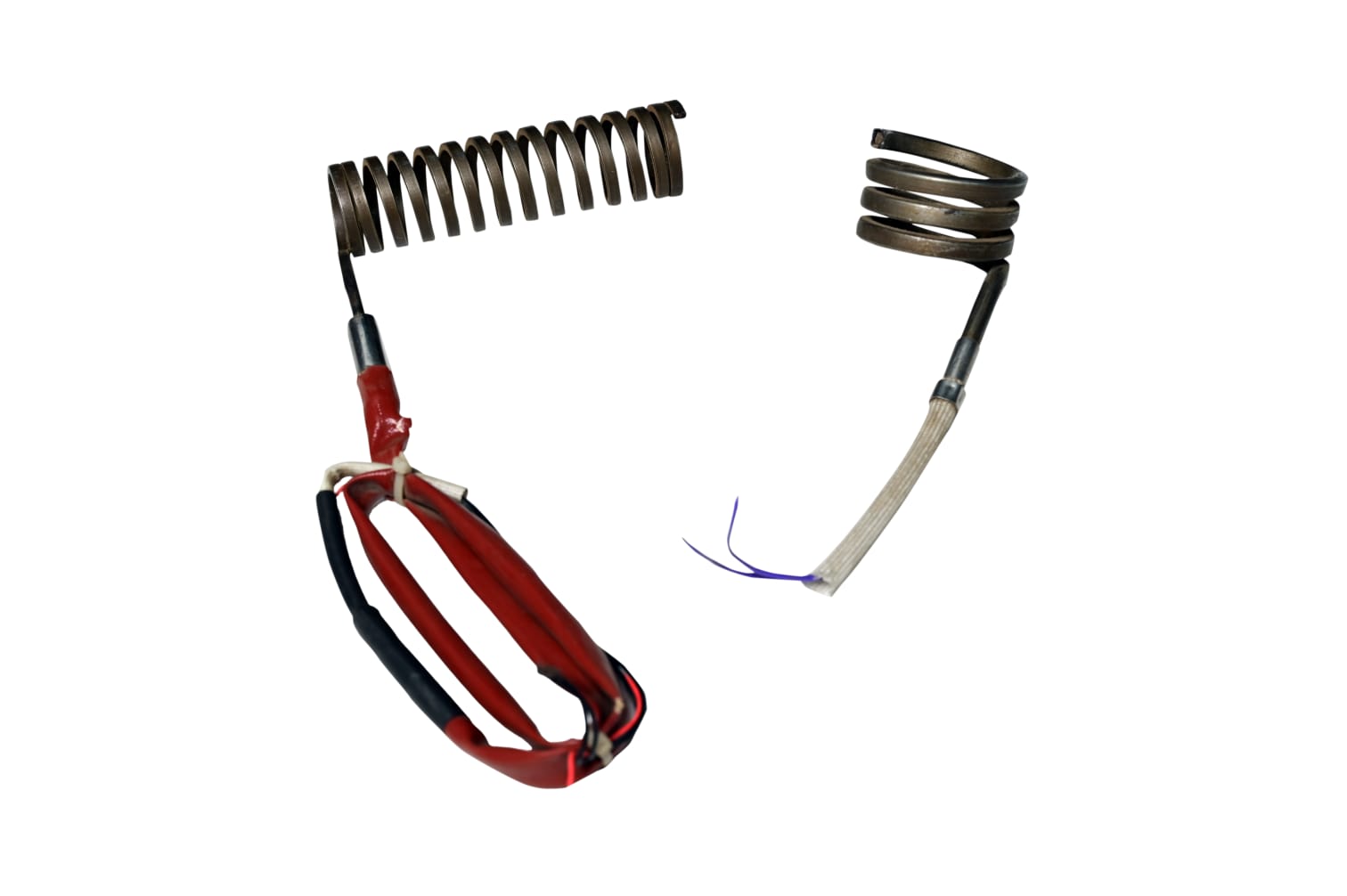

Hot Runner Heaters are precision-engineered heating elements designed for injection molding systems, playing a crucial role in ensuring the efficient and controlled melting of thermoplastic materials. These heaters are strategically positioned within the mold to maintain optimal temperatures in the channels or "runners" through which molten plastic flows, preventing premature cooling and ensuring uniform distribution during the molding process.

Crafted with high-quality materials, Hot Runner Heaters offer rapid and precise heating, contributing to faster production cycles and enhanced product quality. The design of these heaters minimizes energy consumption by focusing heat precisely where it's needed, reducing waste and promoting cost-effectiveness in manufacturing operations.

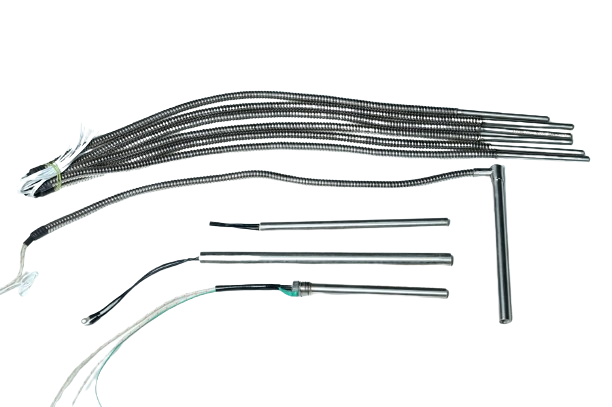

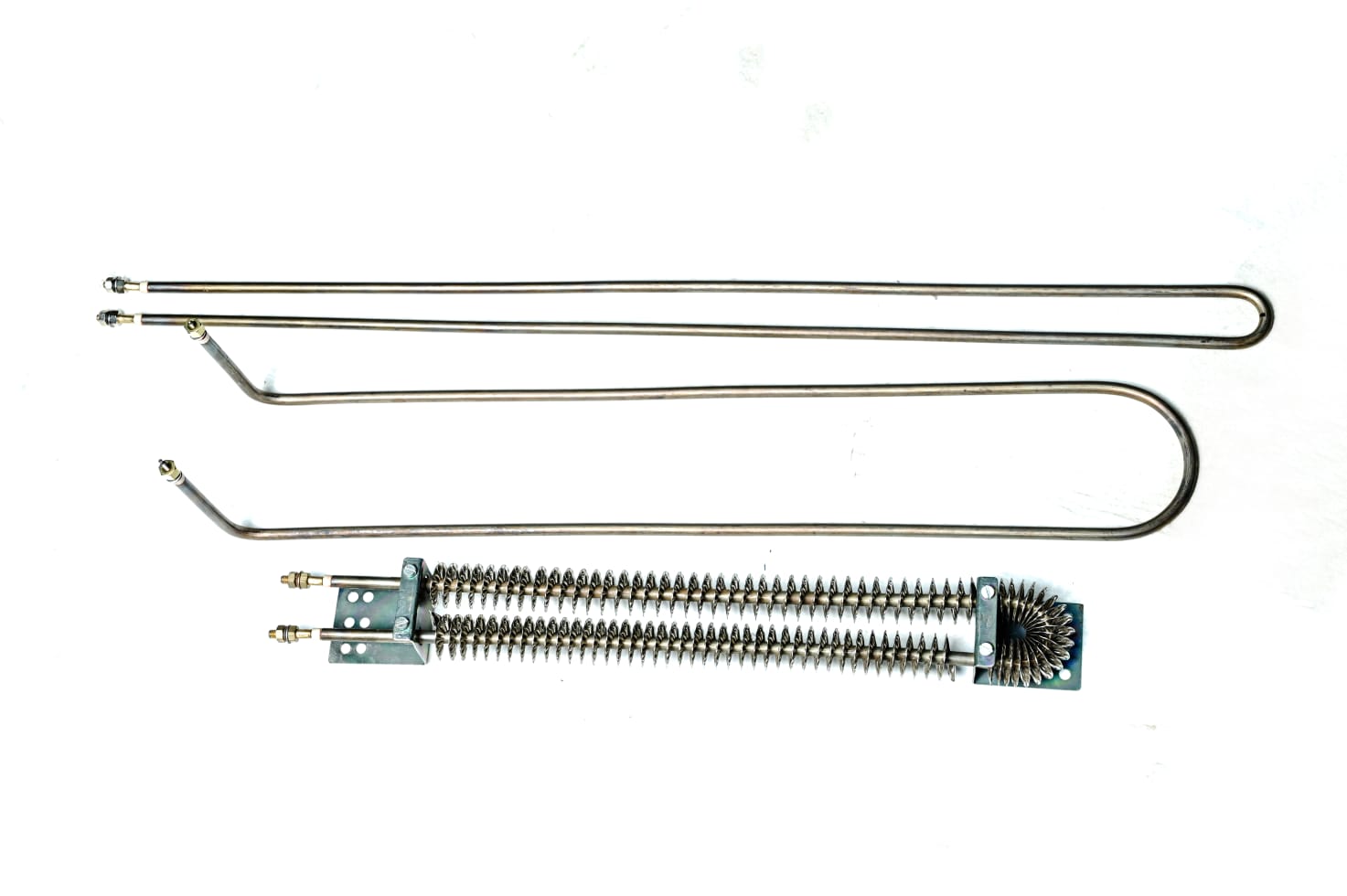

Hot Runner Heaters come in various configurations, including nozzle and manifold types, catering to different injection molding setups. Their durability and resistance to corrosion ensure a prolonged service life, making them a reliable component in industrial settings.

Key features of Hot Runner Heaters include excellent temperature control, quick response times, and compatibility with various thermoplastic materials. These heaters contribute significantly to the overall efficiency and consistency of injection molding processes, making them an integral component for industries seeking high-performance and reliable solutions in plastic manufacturing.